News & Events

Stay up to date with all of the latest industry and legislative news relating to the safety and maintenance of workplace equipment.

We will post blogs relating to HSE prosecutions and HSE accident statistics, safety initiatives and topical events relating to equipment safety and the consequences of failing to maintain equipment at work across a wide range of industries – from farming to construction, warehousing to transport and logistics. In addition we will highlight how our Good to Go Safety inspection systems could help to improve workplace safety and help your company to reduce maintenance costs while complying with key statutory legislations such as PUWER, LOLER and WAHR.

Workers arm dragged into machine at textile factory

- Author Good to Go Safety

- 0

- 681 Views

A textiles company has been fined £60,000 after an employee suffered serious injuries their right arm in an incident at a factory operated by Pin Croft Dyeing and Printing Co. Limited in Market Street, Adlington, on 20 June 2022.

An investigation by the Health and Safety Executive (HSE) found the employee had been operating a large fabric spooling machine when the brake malfunctioned. During an attempt to manually slow the rotation of the machine, he broke both major bones in his forearm ...

Employee sustains extensive injuries after being dragged into machine

- Author Good to Go Safety

- 0

- 597 Views

An investigation by the Health and Safety Executive (HSE) found that a manufacturer of paper and cardboard (Amberset Limited) failed to regularly review safety measures on their machinery and equipment to ensure that access to hazardous parts was prevented. The HSE found that the safety of the paper rewinder had not been reviewed since August 1998.

If Amberset Limited had conducted safety inspections on their machinery and equipment they would have spotted that the paper rewinder was not ...

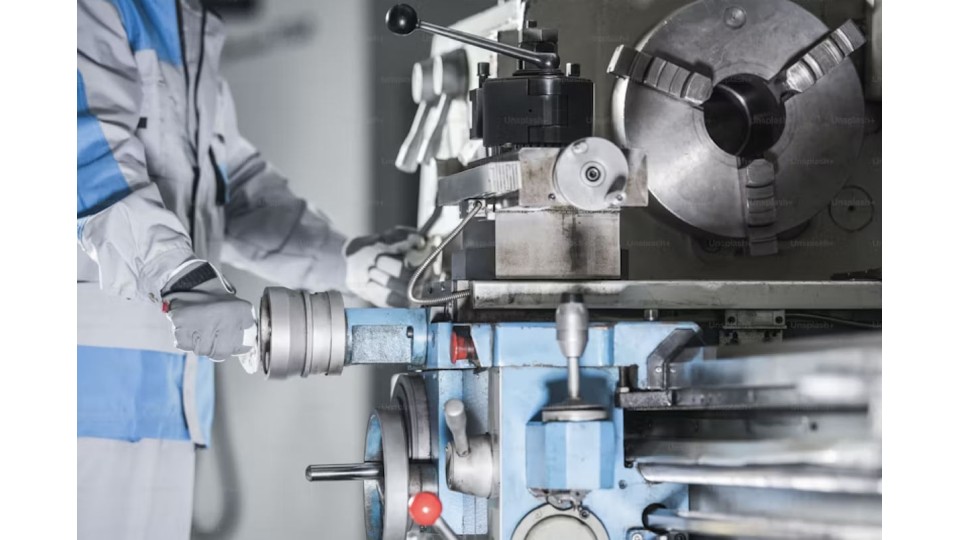

Maintaining Work Equipment

- Author Good to Go Safety

- 0

- 519 Views

Since January the 1st 2021 the rules and procedures regarding work place maintenance of machinery and equipment has changed. In order to ensure that work place machinery and equipment doesn't deteriorate to the extent that it may put people in harms way, employers are required by PUWER (The Provision and Use of Work Equipment Regulations 1998) to maintain it to a good standard.

Effective maintenance of work place machinery and equipment can not only help businesses meet the expectations o...

Showing 1 to 3 of 3 (1 Pages)