Ladder Inspections - Workplace Inspection Checklists

Employers need to make sure that any ladder or stepladder is

both suitable for the work task and in a safe condition before use.

Accounting for around a quarter of all worker fatalities and 8% of all non-fatal injuries every year, falling from height (many involving falling from a ladder) remains the main cause for workplace fatalities.

The law says that ladders can be used for work at height when an assessment of the risk for carrying out a task has shown that using equipment offering a higher level of fall protection is not justified because of the low risk and short duration of use, or there are existing workplace features which cannot be altered. Before starting a task, you should have access to user instructions from the ladder manufacturer in case you need to refer to them. You should always carry out a ‘pre-use’ check to help spot any obvious visual defects and to ensure the ladder is safe to use.

A pre-use check should be carried out:

• by the user;

• at the beginning of the working day;

• after something has changed, eg a ladder has been dropped or moved from a dirty area to a clean area (check the state or condition of the feet).

As a guide, only use ladders or stepladders that:

• have no visible defects. They should have a pre-use check each working day;

• have an up-to-date record of the detailed visual inspections carried out regularly by a competent person. These should be done in accordance with the manufacturer’s instructions. Ladders that are part of a scaffold system still have to be inspected every seven days as part of the scaffold inspection requirements;

• are suitable for the intended use, ie are strong and robust enough for the job;

• have been maintained and stored in accordance with the manufacturer’s instructions.

A detailed visual inspection is similar to pre-use checks, in that it is used to spot defects and can be done on site by a competent employee. Pre-use checks make sure that a ladder is safe to use and are for the immediate benefit of the ladder user. These checks do not need to be recorded. Any problems or issues should be reported to a manager. Detailed visual inspections are the responsibility of the employer. They should be carried out at fixed intervals and recorded. Records of these inspections provide a snapshot of the state of the ladders over time.

The HSE & Ladder Association’s LA455 Guidance Document (Safe Use of Ladders and Stepladders - A brief guide) is a recommended reference tool which can be found on Legislation & Regulations

Good to Go Safety enables a status tag to be attached to ladders and used in conjunction with our comprehensive ladder safety inspection checklist to ensure essential pre-use ladder checks are completed. Using a ladder checklist helps to reduce the risk of a faulty ladder being used which could result in a fall from height. This ladder management system eradicates the assumption that the ladder is safe to use and enforces a ladder safety inspection to be completed prior to use providing compliance with PUWER, INDG402, WAHR & HSE regulations and in line with industry best practice.

The status tag is designed to fit on most industrial ladders (BS EN 131, BS 2037 Class 1, or BS 1129 ladder or stepladder) and we recommend positioning it at eye level near the grip point on the stiles for maximum visibility. Our quick, easy to use, ladder inspection system ensures that key safety checks are carried out prior to use. Once completed the checklist is placed inside the tag to provide a clear visual indication of the ladder's status and date of inspection. This clearly identifies when a ladder is 'Good to Go' and importantly when it is not safe to use. The Good to Go Safety system also allows the clear identification and instant quarantine of any faulty ladders. A duplicate copy of each completed checklist is retained inside the check book for management records, providing clear evidence and audit trails should there be an accident involving the ladder in question.

The Good to Go Safety Ladder Checklist System is flexible and adaptable to suit the needs of any business. It's suitable for monitoring every type of ladder in your business and supports the need for regular ladder safety inspections in line with PUWER and Health & Safety policies. Whether you wish to inspect your ladder daily, weekly or on an ad-hoc basis, Good to Go Safety's ladder tagging and checklist system provides the perfect solution.

Ladder Inspection Books - 25 Checklists

Users should carry out a thorough pre-use visual and functional inspection before setting up a ladde..

£6.50

Ladder Inspections - Weekly Checklist Kit

Spot potential faults on ladders before they develop into a more serious and costly defect. WAH..

£39.50

Ladder Inspections - Daily Checklist Kit

Good to Go Safety is a Safe Equipment Management System (SEMS) that allows workers to carry out a pr..

£115.00

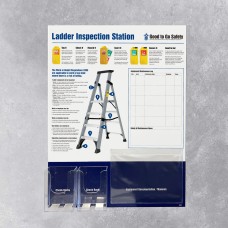

Ladder Inspection and Maintenance Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

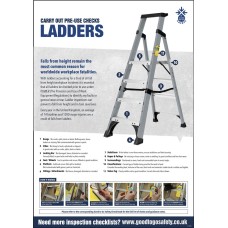

Ladder Poster - Visual Inspection Checklist

The Ladder Safety Poster has been created to promote awareness of safe ladder use and to reinforce t..

£21.77

Inspection Wallet and Pen

A handy wallet that not only provides additional protection from the elements but also gives inspect..

£6.20

Weather Resistant Inspection Holder

These industrial strength pockets have a press seal fastening to keep important documents clean and ..

£6.31

Inspection Book Dispenser

Allow the storage of checklists in a central location for quick and easy access to important inspect..

£13.25