Construction Site Inspections - Workplace Inspection Checklists

Accidents occur every day in the construction industry, almost every conceivable hazard exists within this constantly changing working environment.

The construction industry accident fatality rate stands at more than double that of the all sector average. Health and Safety is a fundamental requirement in any construction business and must be regarded as an essential part of maintenance and management. Assuming equipment is safe to use is a common problem in the industry, leading to catastrophic consequences. Help your construction site become safer, healthier and stronger by using our range of preventative maintenance management products.Preventative maintenance and management of dangerous construction site equipment can bring the following benefits:

• a reduction in injuries and the resulting financial and personal costs;

• better construction practice to help develop a sustainable business

• longer life for equipment and machinery;

• reduced repair costs resulting from unnoticed equipment faults;

• less chance of enforcement action and its costs, eg the cost of dealing with an incident and/or fines;

• reduced risk of damage to the reputation of the business;

• improved productivity, good morale and a happier, healthier workforce;

Equipment is constantly being used and moved on a construction site. Different trades will involve greater demands, but all involve some degree of risk. Whenever an employee is required to use workplace equipment (such as Excavators, MEWPS, Scaffold Towers etc), safety inspections must be carried out. Records of these checks must be maintained for verification. Responsible employers are aware of their duty of care to employees, visitors, and those that may be affected by their activities, and will manage the site effectively, implementing appropriate preventative maintenance inspections in order to reduce costs and accidents.

Front Loader Inspections - Weekly Checklist Kit

Loader bucket trucks (also known as shovel loaders or front loaders) have the capacity to cause seri..

£39.50

Scaffold Tower Inspections - Weekly Checklist Kit

One of the main reasons for incidents occurring with Scaffold Towers is due to flaws in its erection..

£39.50

Telehandler Inspections - Weekly Checklist Kit

The continuing development of telehandlers (telescopic materials handlers) in terms of capacity and ..

£39.50

Create Your Own Inspections - Weekly Checklist Kit

Good to Go Safety is a Safe Equipment Management System (SEMS) which allows workers to carry out pre..

£39.50

Excavator Inspections - Daily Checklist Kit

According to the HSE: “A programme of daily visual excavator safety inspection checklist checks and ..

£115.00

Scaffolding (Fixed) Inspections - Daily Checklist Kit

Good To Go Safety helps employers meet their legal responsibilities through the use of an innovative..

£115.00

Harness Inspections - Daily Checklist Kit

Carry out pre-use checks and spot potential faults before they develop into a more serious and costl..

£115.00

MEWP Inspections - Daily Checklist Kit

Improve workplace safety and reduce maintenance costs on your MEWPs by carrying out safety inspectio..

£115.00

Dumper Truck Inspections - Daily Checklist Kit

Tipper accidents are a common problem within the construction and quarry industries, often causing s..

£115.00

Front Loader Inspections - Daily Checklist Kit

Loader bucket trucks (also known as shovel loaders or front loaders) have the capacity to cause seri..

£115.00

Scaffold Tower Inspections - Daily Checklist Kit

One of the main reasons for incidents occurring with Scaffold Towers is due to flaws in its erection..

£115.00

Telehandler Inspections - Daily Checklist Kit

The continuing development of telehandlers (telescopic materials handlers) in terms of capacity and ..

£115.00

Create Your Own Inspections - Daily Checklist Kit

Good to Go Safety is a Safe Equipment Management System (SEMS) which allows workers to carry out pre..

£115.00

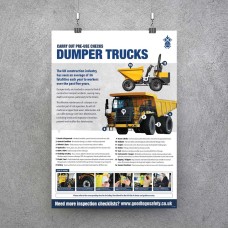

Dumper Truck Poster - Visual Inspection Checklist

Our dumper truck safety poster has been designed to highlight key components of a tipper truck and r..

£21.77

Excavator Poster - Visual Inspection Checklist

Our excavator safety poster has been designed to highlight key components of excavator and reinforce..

£21.77