Warehouse Inspections - Workplace Inspection Checklists

Accidents occur every day in warehouses and factories. Around 1,300 UK employees are hospitalised each year with serious injuries due warehouse accidents.

Incidents involving pallet rack collapses often happen due to two reasons: Products not being properly stored in a safe and orderly manner or Collisions and unseen damage which weakens the rackings structural integrity. Using our racking inspections regularly will ensure that potential dangers and issues can be identified quickly helping to prevent costly accidents.

Forklift and pallet truck accidents are a common problem within warehouses, often causing serious injury and in some cases death. It is vital that vehicles such as forklifts, MEWPS and pallet trucks are checked prior to use for any faulty components that might cause an incident to occur.

Health and Safety is a fundamental requirement in any business and must be regarded as an essential part of maintenance and management. Assuming equipment is safe to use is a common problem in warehouses and factories, which leads to catastrophic consequences. Help your warehouse become safer, healthier and stronger by using our range of preventative maintenance management products.

Preventative maintenance and management of warehouse equipment can bring the following benefits:

• a reduction in injuries and the resulting financial and personal costs;

• better construction practice to help develop a sustainable business

• longer life for equipment and machinery;

• reduced repair costs resulting from unnoticed equipment faults;

• less chance of enforcement action and its costs, eg the cost of dealing with an incident and/or fines;

• reduced risk of damage to the reputation of the business;

• improved productivity, good morale and a happier, healthier workforce;

Whenever an employee is required to use workplace equipment (such as Ladders, MEWPS, Racking, Forklifts etc), safety inspections must be carried out. Records of these checks must be maintained for verification. Responsible employers are aware of their duty of care to employees and those that may be affected within a warehouse, and will manage their warehouse effectively, implementing appropriate preventative maintenance inspections in order to reduce costs and accidents.

Create Your Own Inspections - Daily Checklist Kit

Good to Go Safety is a Safe Equipment Management System (SEMS) which allows workers to carry out pre..

£115.00

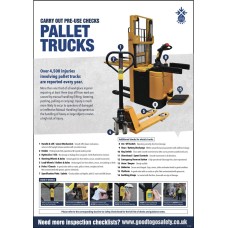

Pallet Truck Poster - Visual Inspection Checklist

Our pallet truck safety poster has been designed to highlight key components of pallet trucks and re..

£21.77

Forklift Inspection and Maintenance Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

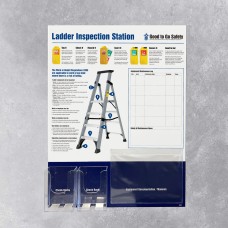

Ladder Inspection and Maintenance Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

MEWP Inspection and Maintenance Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

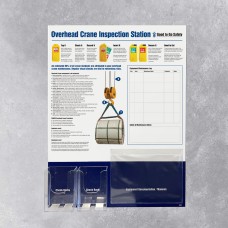

Overhead Crane Inspection and Maintenance Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

Pallet Truck Inspection and Maintenance Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

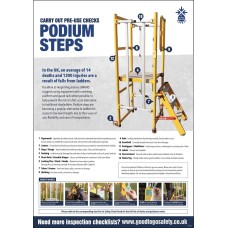

Podium Step Poster - Visual Inspection Checklist

Our podium step safety poster has been designed to highlight key components of a podium step ladder ..

£21.77

Racking Inspection and Maintenance Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

Racking Poster - Visual Inspection Checklist

Our racking safety poster has been designed to highlight key components of pallet racking and reinfo..

£21.77

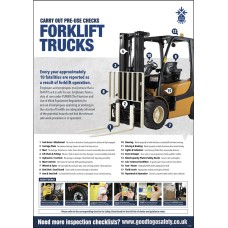

Forklift Poster - Visual Inspection Checklist

Our forklift truck safety poster has been designed to highlight key components of forklift trucks an..

£21.77

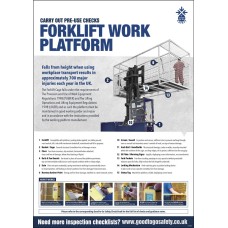

Forklift Work Platform Poster - Visual Inspection Checklist

Our forklift work platform poster has been designed to highlight key components of forklift work pla..

£21.77

Front Loader Poster - Visual Inspection Checklist

Our front loader (shovel loader) poster has been designed to highlight key components of front loade..

£21.77

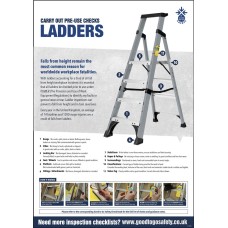

Ladder Poster - Visual Inspection Checklist

Our ladder safety poster has been designed to highlight key components of ladder and reinforce the i..

£21.77

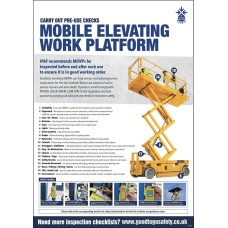

MEWP Poster - Visual Inspection Checklist

Our Mobile Elevating Work Platform (MEWP / Scissor Lift / Boom) safety poster has been designed to h..

£21.77