Racking Inspections - Workplace Inspection Checklists

The vast weight of goods falling from height can have a devastating impact

Any racking collapse, regardless of severity, has the potential to kill. A racking collapse can cause damage to stock, bring a business to a halt, and pose a threat of serious injury.

The chances of racking system damage increase exponentially when a forklift is involved. Due to its dynamic movements and heavy weight, this powered truck has a high potential of hitting the pallet racks. However, the risk can be significantly reduced by providing proper training to forklift operators, increasing the width of aisles, and safeguarding racking with protection devices such as rack guards. If racking is hit by a forklift, there is a high possibility that the driver will not report it (in fear of reprimand), which further highlights the importance of regular visual checks to identify any evidence of impact on the uprights.

When it comes to rack failure, many factors contribute towards a racking collapse. The most common reasons are due to system overload, incorrect installation, lack of maintenance, poor layout and staff negligence, use of damaged pallets, and collisions with forklifts. In most cases, it stems from a combination of more than one of those factors.

By assuming your racking is safe you run the risk of a racking collapse and potential:

• Injury/death to employees

• Fines and prosecution

• Damage to plant, equipment, and stored goods

• Cost of temporary storage, whilst new racking is installed

• Downtime and lost hours because of the accident and subsequent investigations

• Legal, compensation and insurance costs

• Damaged morale & public image, resulting in a loss of business

Failure to maintain pallet racking can be a costly mistake to make, as highlighted above. To keep your pallet racking in its best condition we would recommend the following:

• Carry out routine visual inspections for any damage, using our Good to Go Safety Racking Checklist systems.

• Ensure that any damage to warehouse racking is reported immediately. Avoid using the pallet racking until it is repaired. The Good to Go Safety Status Tag helps inform and advise of damage.

• Operate and maintain pallet racking in line with manufacturer guidelines.

• Have a thorough examination carried out annually or if you notice damage to your system. Choose a SEMA approved racking inspector who will provide you with a full damage report.

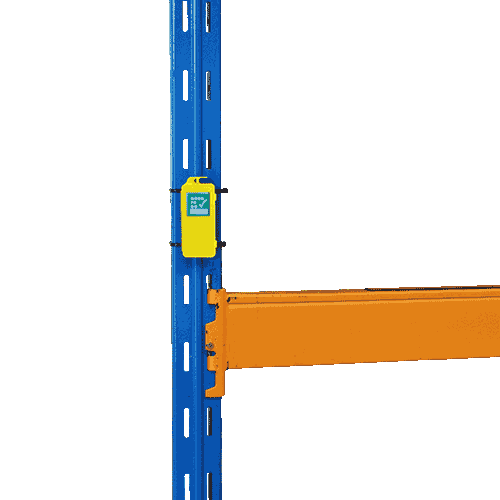

Good to Go Safety ensures pallet racking is inspected using the pallet racking safety inspection checklist as part of a routine maintenance management system. It promotes a visual safety inspection check of all racking bays at the start of each daily shift, clearly identifying if the racking is good to go. Providing compliance with PUWER, WAHR, HSE & SEMA regulations and best practice. We recommend that a tag be located on the end of each racking bay/aisle alongside the safe working load (SWL) sign for maximum visibility. Our racking checklist covers checks of the racking structure, loads found on the racking and general housekeeping of the racking area.

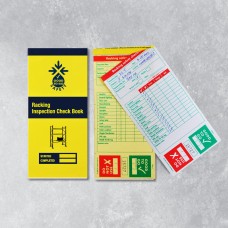

The racking check book contains 25 individual checklists. A completed checklist is removed and placed inside the tag on the racking to display the date and the findings of the inspection, while a duplicate copy remains in the book as evidence of the maintenance procedure for management records. If a fault is found, the tag can be used to display a clear “Do Not Use” message and effectively quarantine use of the racking until repairs are carried out. The same system can be replicated on other warehouse equipment such as forklifts or pallet trucks by using the relevant checklists – providing a consistent and efficient approach to equipment maintenance and safety.

Racking Inspection Books - 25 Checklists

Improving warehouse safety and reducing maintenance costs starts with regular pallet racking inspect..

£6.50

Racking Inspections - Weekly Checklist Kit

Improve safety in your warehouse and reduce maintenance costs on your equipment by carrying out pa..

£39.50

Racking Inspections - Daily Checklist Kit

Improve safety in your warehouse and reduce maintenance costs on your equipment by carrying out pa..

£115.00

Racking Inspection and Maintenance Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

Racking Poster - Visual Inspection Checklist

Enhance warehouse safety with our pallet racking safety poster, designed to clearly illustrate the e..

£21.77

Inspection Wallet and Pen

A handy wallet that not only provides additional protection from the elements but also gives inspect..

£6.20

Weather Resistant Inspection Holder

These industrial strength pockets have a press seal fastening to keep important documents clean and ..

£6.31

Inspection Book Dispenser

Allow the storage of checklists in a central location for quick and easy access to important inspect..

£13.25