Overhead Crane Inspections - Weekly Checklist Kit

- Product Code: 51352

- Contact us for any queries

-

£39.50

- Workplace Inspections for Overhead Crane Inspections - Weekly Checklist Kit. Inspections also available for equipment such as Forklifts, Ladders, Scaffolding, Scaffold Towers, Harnesses, MEWPs, Podium Steps, Pallet Trucks, Pallet Racking, Fleet Vehicles - Cars & Vans, Excavators, Trailers, Tractors, Tow Tractors, Loader Cranes, Overhead Cranes, Telehandlers

Overhead cranes must be thoroughly examined at least every twelve months to comply with LOLER. It is important however not to rely solely on the annual LOLER inspection; companies should also complete regular visual checks throughout the intervening period and that is where the Good to Go Safety system comes into its own. Around a quarter of all crane incidents involve a dropped load, an estimated 60% of which could be attributed to poor crane maintenance and 15% to the failure of wire ropes/cables. It allows workers to carry out pre-use checks and spot potential faults before they develop into a more serious and costly defect. These safety checklists are designed to help improve safety, reduce maintenance costs and ensure compliance with legal responsibilities.

A programme of pre-use checks, regular inspections and servicing schedules should be established in accordance with the manufacturers instructions and the risks associated with using an overhead crane. Operators should be encouraged to report defects or problems. Reported problems should be put right quickly, with the crane or associated attachment(s) taken out of service if safety critical. The overhead crane must be thoroughly examined at least every twelve months to comply with LOLER.

Each kit comes in a sturdy highly visible box which is ideal for storing used checkbooks for management records. The kit contains 50 individual (one for each week) inspections relating to the components and structural integrity of a overhead crane. Duplicate carbon copies of the completed inspection checklists are retained in the book for management records. The book also includes useful guidance notes to remind operatives what to look for during their inspection. A status tag which when positioned and attached on overhead crane is a ideal way to advise employees when the equipment is "Good to Go" following a pre-use inspection. If a fault is found then the tag can display a "Do Not Use" message to quarantine the equipment until repaired and another inspection deems the overhead crane is safe for use. A useful wallet and pen which securely holds the book and pen to protect it from general wear and tear whilst providing a perfect writing surface whilst on the move. The kit also provides 100 tamper evident seals which provide a visual indicator that the checklist insert is in place and verified.

Weekly Overhead Crane Inspection Kit includes:

• 1 x Status Tags to attach to the equipment and show its status.

• 2 x Safety Check Books provide 50 individual checklists, allowing one to be completed each week and the findings displayed inside the status tag. Additional books can be ordered as and when required.

• 1x Check Book Wallet & Pen, to store the current book and provide a suitable writing surface when completing checklists.

• 100 x Tamper Evident Seals, which can be used to deter and identify unauthorised access to the status tag.

Related Products

Tamper Evident Seals

Tamper Evident Seals are an optional extra which can provide a visual indicator that the checklist i..

£14.06

Weather Resistant Inspection Holder

These industrial strength pockets have a press seal fastening to keep important documents clean and ..

£6.31

Overhead Crane Inspections - Daily Checklist Kit

Overhead cranes must be thoroughly examined at least every twelve months to comply with LOLER. It is..

£115.00

Overhead Crane Inspection Books - 25 Checklists

Overhead cranes are critical pieces of equipment in many industrial environments, and their safe ope..

£6.50

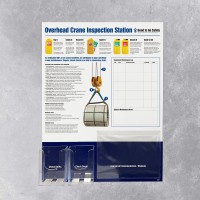

Overhead Crane Inspection and Maintenance Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

Tags: 51352, Warehouses, Factory, Factories, Maintenance, Inspections, Audit, Form, Tagging, PUWER, LOLER, Safety, Record, Check, Books, Checklists, Checklist, Inspection