MEWP Inspections - Workplace Inspection Checklists

Reports from seven countries shows 10 fatalities and 66 injuries in 2021.

In the past three years there were 124 reports from 12 countries, including 23 fatalities – almost double (91.7%) the ten-year yearly average.

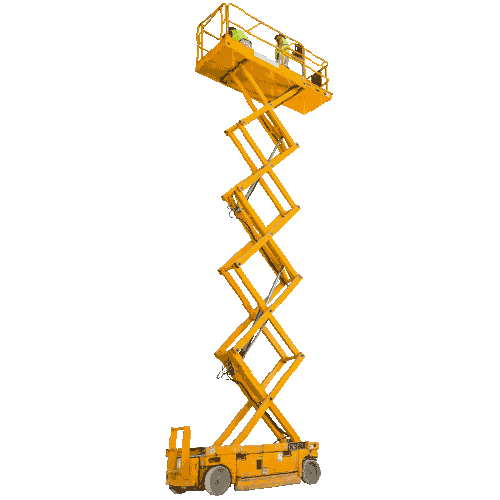

Over the past 10 years there have been 39 deaths due to mechanical or technical MEWP failures alone.Mobile Elevated Work Platforms (MEWPs) are commonly used across all industrial sectors by a whole variety of trades, including mechanical and electrical contractors, and painters and decorators, as a safer, temporary method of working at height. The industry sector with the most fatalities was construction, accounting for just over half of all fatalities, while arboriculture accounted for 20.5%. There is a large range of MEWPs on the market and their controls and functionality varies depending on the category, manufacturer, model and size of machine. Types of MEWP can often be referred to as scissor lifts, articulating booms, telescopic booms and/or cherry pickers (amongst others).

Data collated by IPAF (The International Powered Access Federation) from 2012-2021 indicates 4,374 reports, including 4,462 lost-time incidents (LTIs) of which there were 585 fatalities. There have been 41 countries from which reports have been gathered across the whole ten-year period. In 2021 alone, there were 603 reports from 28 countries, with 628 people involved in these incidents, which resulted in 109 fatalities.

One way to reduce the likelihood of a mechanical or technical failure is to carry out regular inspections of the equipment by qualified personnel. Failure to carry out inspections and ongoing maintenance can result in mechanical or technical failures. There are different types of inspections that must be carried out on a MEWP: Pre-hire inspections carried out by MEWP rental companies; pre-use inspections by an operator; periodic maintenance inspection by a qualified engineer/technician; routine and non-routine maintenance carried out by the rental company; major inspections carried out by a qualified engineer/technician; Original Equipment Manufacturer (OEM) service instructions and safety bulletins implementation; mandatory parts replacement by a qualified engineer/technician.

It is imperative MEWP inspections are carried out – complacency will lead to incidents and accidents occurring, this can be prevented by carrying out pre-use and periodical inspections. MEWPs that are regularly inspected are less likely to be subject to mechanical or technical failures.

A mobile elevating work platform (MEWP) must be inspected daily or at the start of each shift to make sure it is: Safe to use; and will not cause an injury to the platform occupants or other personnel. Your employer must provide you with adequate training to enable you to operate the equipment safely and be aware of any associated risks. You must record evidence of the daily pre-use inspection.

Before carrying out a pre-use inspection you must:

1. Ensure you are trained in the category of MEWP about to be used;

2. Ensure you are familiarised on the specific model.

Before carrying out a pre-use inspection you must:

1. Isolate the machine;

2. Tag the equipment to also inform other potential operators in the area that the machine has a fault; and

3. Report the fault to your employer and the MEWP owner.

The IPAF GLOBAL SAFETY REPORT 2022 contains a detailed breakdown of accident data and statistics relating to MEWPs and is a recommended reference point for anyone involved with the operation of MEWPs. Click here for more information.

The Good to Go Safety MEWP safety inspection checklist helps companies comply with PUWER, LOLER, WAHR, CDM, IPAF & HSE legislation and best practice. The highly visible tag can be positioned by the point of entry to remind operatives to carry out a pre-use MEWP safety inspection checklist and to advise of the findings of said MEWP safety inspection. The MEWP safety inspections checklist is used to carry out essential visual checks of the MEWP to help highlight any potential issues and to identify when it is good to go. This essential MEWP safety inspection checklist can be used in conjunction with the MEWP manufacturer's manual.

IPAF recommends the MEWP should be inspected both before and after use to ensure it is safe, complete, working properly and clean. The guidelines and MEWP safety inspection checklist supplied by Good to Go Safety are a perfect supplement to the instructions and training already given to operatives. If a safety problem is identified, or any uncertainties are raised with the MEWP safety inspection checklist, the status display should be immediately updated to “DO NOT USE” whilst advice is sought from the site manager, supervisor or safety officer.

By placing a completed checklist inside the Good to Go Safety Status Tag it provides a clear visual confirmation of the date of inspection and the findings, removing any unfounded risk of assumption that the inspection has been completed. A duplicate record is left inside the check book for management records.

Useful downloads can be found in Legislation & Regulation. BS EN 365:2004 and BS 8437 also contain information on periodic safety inspection of fall protection.

MEWP Inspection Books - 25 Checklists

Regular safety inspections are a critical component of maintaining workplace safety and ensuring the..

£6.50

MEWP Inspections - Weekly Checklist Kit

Improve workplace safety and reduce maintenance costs on your MEWPs by carrying out safety inspectio..

£39.50

MEWP Inspections - Daily Checklist Kit

Improve workplace safety and reduce maintenance costs on your MEWPs by carrying out safety inspectio..

£115.00

MEWP Inspection and Maintenance Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

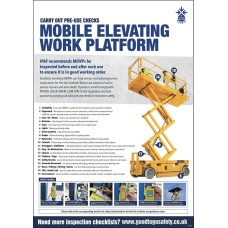

MEWP Poster - Visual Inspection Checklist

Our Mobile Elevating Work Platform (MEWP / Scissor Lift / Boom) safety poster has been designed to h..

£21.77

Inspection Wallet and Pen

A handy wallet that not only provides additional protection from the elements but also gives inspect..

£6.20

Weather Resistant Inspection Holder

These industrial strength pockets have a press seal fastening to keep important documents clean and ..

£6.31

Inspection Book Dispenser

Allow the storage of checklists in a central location for quick and easy access to important inspect..

£13.25