Loader Crane Inspections - Workplace Inspection Checklists

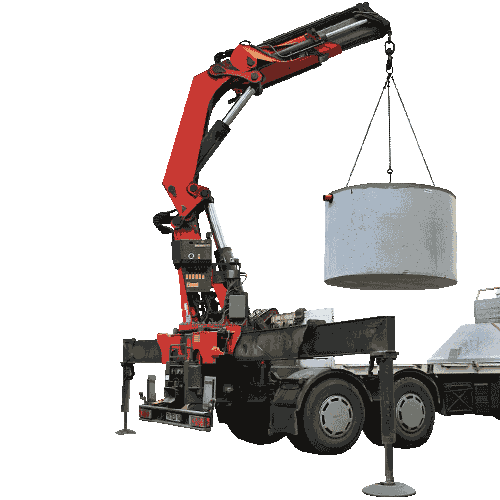

Lorry loaders are complex machines with electrical, mechanical and hydraulic systems

Over the past few years there have been a significant number of accidents involving the use of lorry loaders, which have tragically included fatalities.

In recent years lorry loaders have developed significantly, to the stage where they are able to carry out many of the tasks traditionally undertaken out by mobile and tower cranes. When used safely they make a valuable contribution to the carrying out of lifting operations, however it should not be forgotten that all lifting operations must be planned and executed to the same standard, irrespective of the type of lifting equipment being used.

The effective maintenance of a lorry loader is an essential part of safe operation. As with all lifting machines the lorry loader wears and deteriorates over time and the maintenance process, including checks and inspections, both monitors, prevents and rectifies this deterioration. It is important that the personnel asked to carry out these tasks have the necessary machine-specific training, experience and competence in both periodic and breakdown maintenance.

Lorry loaders are complex machines with electrical, mechanical and hydraulic systems that require the manufacturer’s preventative maintenance instructions to be strictly complied with, if safety is to be maintained in use. Checks and inspections should be carried out taking account of the frequency of use of the lorry loader and the environmental conditions in which it regularly works. If the operator is considered to be competent, they may be authorised to carry out routine pre-use checks and intermediate inspections.

The employer of the person carrying out these checks should ensure that the machine is taken out of use for the period of time required to carry them out. Also, the employer or authorised person carrying out the checks and inspections should ensure that a safe system of work is in place to prevent personnel from being exposed to risk, for example from the inadvertent operation of the equipment.

Daily pre-use checks should be completed at the beginning of each shift or working day before work commences and/or when taking over the machine for the first time. A record of the daily check should be kept and a defect reporting system should be in place so that any defects are rectified promptly. These daily checks are designed to compliment the LOLER Thorough Examination (a period not exceeding 12 months, if persons are not lifted, or a period not exceeding 6 months if persons are lifted) to help identify potential concerns in the interim periods.

The Good to Go Safety loader crane inspection checklist has been designed in accordance with BS 7121-4:2010 and will allow the operator to run through safety critical loader crane inspection checks and record the findings. If any defects are found during the inspection, which are detrimental to the safe operation of the machine, then it must not be used until management has been informed and repairs have been completed.

By displaying the date and findings of each completed loader crane inspections checklist on the machine it ensures everyone knows when the crane is Good to Go. By attaching the Good to Go Safety Tag next to the loader crane control panel it helps remind operators to complete an inspection before use – the completed checklist is then placed inside the tag to clearly display the status and date of the inspection. A duplicate copy of the lorry loader checklist is retained inside the check book for management records providing clear evidence of a systematic and effective inspection and maintenance programme.

The Association of Lorry Loader Manufacturers and Importers (ALLMI) Guidance Document (The Management of Lifting Operations with Lorry Loaders) is a recommended reference tool which can be found on Legislations & Regulations.

Loader Crane Inspection Books - 25 Checklists

Lorry loaders are complex machines with electrical, mechanical and hydraulic systems that require th..

£6.20

Loader Crane Inspections - Weekly Checklist Kit

Lorry loaders are complex machines with electrical, mechanical and hydraulic systems that require th..

£37.10

Loader Crane Inspections - Daily Checklist Kit

Lorry loaders are complex machines with electrical, mechanical and hydraulic systems that require th..

£109.50

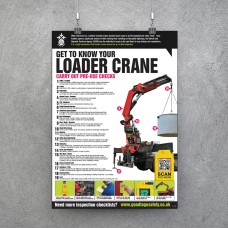

Loader Crane Poster - Visual Inspection Checklist

Our loader crane safety poster has been designed to highlight key components of a loader crane and r..

£21.77

Inspection Information Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

Inspection Wallet and Pen

A handy wallet that not only provides additional protection from the elements but also gives inspect..

£6.20

Weather Resistant Inspection Holder

These industrial strength pockets have a press seal fastening to keep important documents clean and ..

£6.31

Inspection Book Dispenser

Allow the storage of checklists in a central location for quick and easy access to important inspect..

£13.25