Fixed Scaffolding Inspections - Workplace Inspection Checklists

There were 90 RIDDOR accidents reported by NASC members during 2021

Scaffolds must be designed, erected, altered and dismantled only by competent people and the work should be carried out under the direction of a competent supervisor.

Scaffolding must be inspected to ensure it is safe for use. The scaffolding inspection report must note any defects or matters that could give rise to a risk to health and safety and any corrective actions taken, even when those actions are taken promptly, as this assists with the identification of any recurring problem. These inspections help identify if the scaffolds is designed, erected, altered according to a generally recognised standard configuration, such as NASC Technical Guidance TG20 for tube and fitting scaffolds.

It is the scaffold users/hirers responsibility to ensure that all scaffolding has been inspected as follows:

• Following the scaffoldings installation / before first use

• At an interval of no more than every seven days thereafter

• Following any circumstances liable to jeopardise the safety of the installation e.g. high winds

• All scaffolding inspection must be carried out by a competent person whose combination of knowledge, training and experience is appropriate for the type and complexity of the scaffold. Competence may have been assessed under the CISRS or an individual may have received training in inspecting a specific type of system scaffold from a manufacturer/supplier.

A non-scaffolder who has attended a scaffold inspection course, eg a site manager, could be deemed competent to inspect a basic scaffold structure.

The scaffolding inspection report must note any defects or matters that could give rise to a risk to health and safety and any corrective actions taken, even when those actions are taken promptly, as this assists with the identification of any recurring problem.

Good To Go Safety helps employers meet their legal responsibilities through the use of an innovative scaffolding tagging and checklist system. The scaffold status can be instantly updated following any structural alterations, periods of bad weather, as part of its seven day check or daily scaffolding safety inspection checklist programme. Using our scaffolding safety inspection checklist has never been easier and can reduce maintenance costs and the risk of a costly scaffolding collapse or accident.

Using the Good to Go Safety Scaffold safety inspection checklist ensures you're compliant with PUWER, WAHR, CDM, NASC & HSE legislation and best practice. The system is very easy to use, simply attach a tag to the scaffolding tube at point of entry to ensure maximum visibility (the status tag has been designed to sit flush to scaffolding tubes using cable ties to reduce the risk of snagging). Then complete our comprehensive scaffolding safety inspection checklist which has been designed in line with BS EN 12811-1 and TG20 guidance and provides a chronological duplicate record of all scaffolding safety inspection for your maintenance records as required by WAHR and PUWER.

Inserting the completed scaffolding safety inspections into the status tag provides instant visual confirmation that a scaffolding safety inspection has been completed. The safety inspection clearly displays the date and findings for all to see. Unlike other scaffolding safety inspections Good to Go Safety generates a duplicate record of each completed scaffolding safety inspections checklist for management records. This can provide invaluable evidence in the event of an accident involving the scaffolding

NASC Safety Reports can be downloaded for free: click here for more information.

Scaffolding (Fixed) Inspection Books - 25 Checklists

Good To Go Safety helps employers meet their legal responsibilities through the use of an innovative..

£6.20

Scaffolding (Fixed) Inspections - Weekly Checklist Kit

Good To Go Safety helps employers meet their legal responsibilities through the use of an innovative..

£37.10

Scaffolding (Fixed) Inspections - Daily Checklist Kit

Good To Go Safety helps employers meet their legal responsibilities through the use of an innovative..

£109.50

Scaffolding (Fixed) Poster - Visual Inspection Checklist

Our scaffolding poster has been designed to highlight key components of fixec scaffolding and reinfo..

£21.77

Inspection Information Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

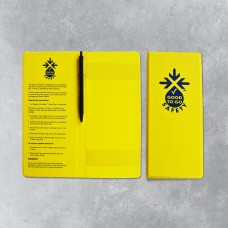

Inspection Wallet and Pen

A handy wallet that not only provides additional protection from the elements but also gives inspect..

£6.20

Weather Resistant Inspection Holder

These industrial strength pockets have a press seal fastening to keep important documents clean and ..

£6.31

Inspection Book Dispenser

Allow the storage of checklists in a central location for quick and easy access to important inspect..

£13.25