Excavator Inspections - Workplace Inspection Checklists

The construction industry has seen an average of 36 fatalities to workers over the past 5 years

The latest estimates (2020/21) show that in UK Construction there were: 61,000 cases of non-fatal work-related injury (41% involved over 3 days and 25% over 7 days absence).

Preventative maintenance of excavators will help prevent break downs and lost valuable work time that could have been avoided. A Good to Go Safety excavator checklist enables daily excavator safety inspections to be completed and recorded before displaying the findings in the status tag for all to see. This essential excavator safety inspection checklist can be used in conjunction with the excavator manufacturer's manual. Helps compliance with PUWER, LOLER, CDM, and HSE legislation and best practice.

The construction industry has seen an average of 36 fatalities to workers and 5 to members of the public each year over the last five years.

Most fatal and serious injuries involving excavators occur when the excavator is:

• Moving – and strikes a pedestrian, particularly while reversing;

• Slewing – trapping a person between the excavator and a fixed structure or vehicle; or

• Working – when the moving bucket or other attachment strikes a pedestrian or when the bucket inadvertently falls from the excavator.

To prevent such accidents:

• Excavators should be equipped with adequate visibility aids to ensure drivers can see in blind spot areas where people may be at risk from the operation of the machine;

• Employees and visitors should be kept away from areas of excavator operation by the provision of suitable barriers;

• A signaller should be provided and in a safe position to direct the excavator's operation and any pedestrian movements;

• A clearance of over 0.5 m needs to be maintained between any part of the machine, particularly the ballast weight, and the nearest obstruction.

• An effective excavator safety inspection checklist maintenance regime should be introduced to identify potential defects and prevent use of faulty excavators.

According to the HSE: “A programme of daily visual excavator safety inspection checklist checks and servicing schedules should be established. Excavator drivers should be encouraged to report defects or problems that are found using the good to go safety excavator safety inspection checklist programme. Reported problems should be put right quickly and the faulty excavator taken out of service if the item is safety critical. Daily excavator safety inspections help ensure that faults are discovered quickly, before they become major issues which could lead to a serious accident”.

Excavator Inspection Books - 25 Checklists

According to the HSE: “A programme of daily visual checks, regular inspections and servicing schedul..

£6.50

Excavator Inspections - Weekly Checklist Kit

According to the HSE: “A programme of daily visual excavator safety inspection checklist checks and ..

£39.50

Excavator Inspections - Daily Checklist Kit

According to the HSE: “A programme of daily visual excavator safety inspection checklist checks and ..

£115.00

Excavator Poster - Visual Inspection Checklist

Our excavator safety poster has been designed to highlight key components of excavator and reinforce..

£21.77

Inspection Information Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

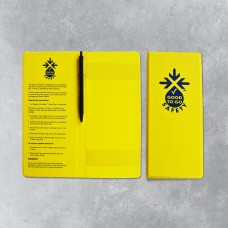

Inspection Wallet and Pen

A handy wallet that not only provides additional protection from the elements but also gives inspect..

£6.20

Weather Resistant Inspection Holder

These industrial strength pockets have a press seal fastening to keep important documents clean and ..

£6.31

Inspection Book Dispenser

Allow the storage of checklists in a central location for quick and easy access to important inspect..

£13.25